AMM745

AMM745

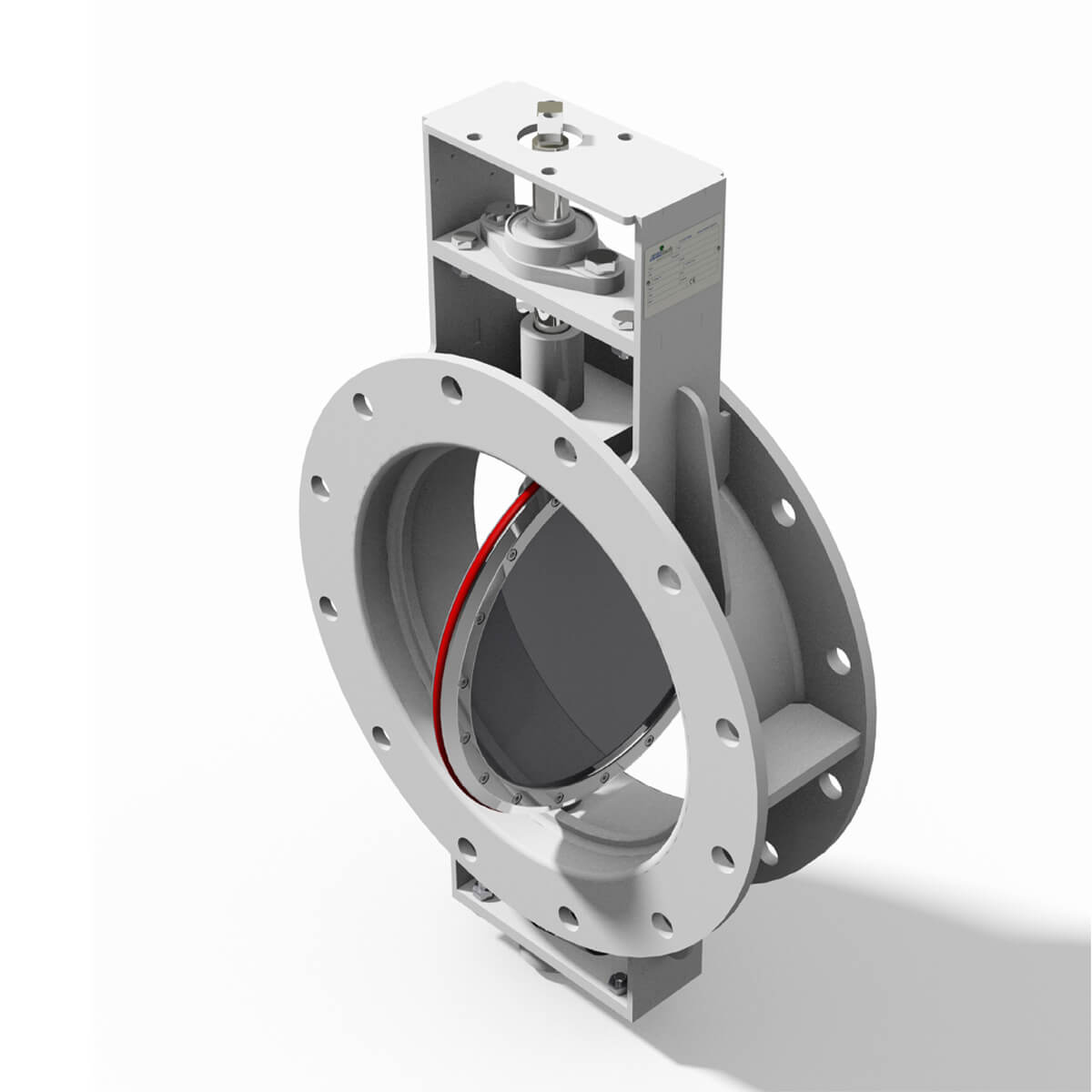

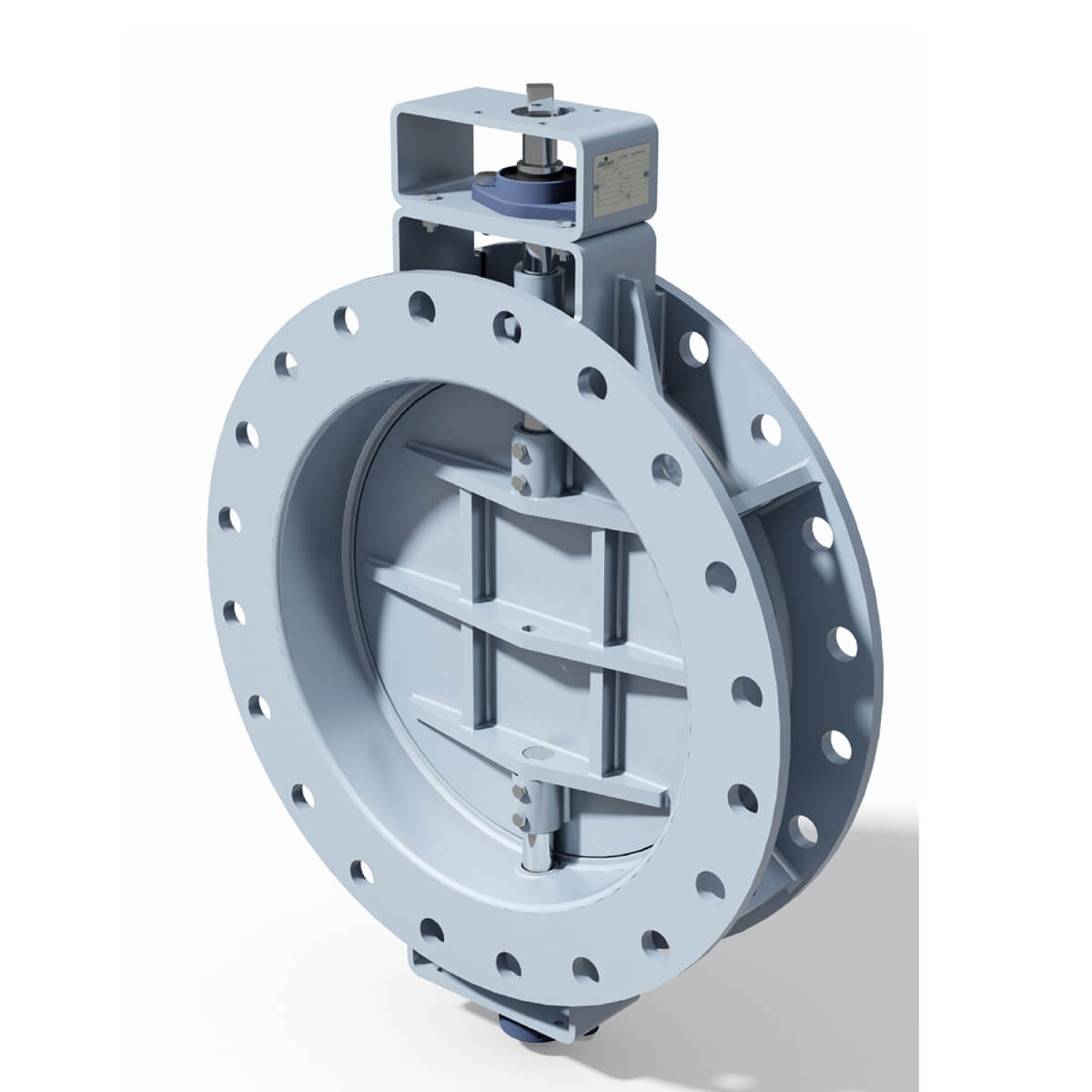

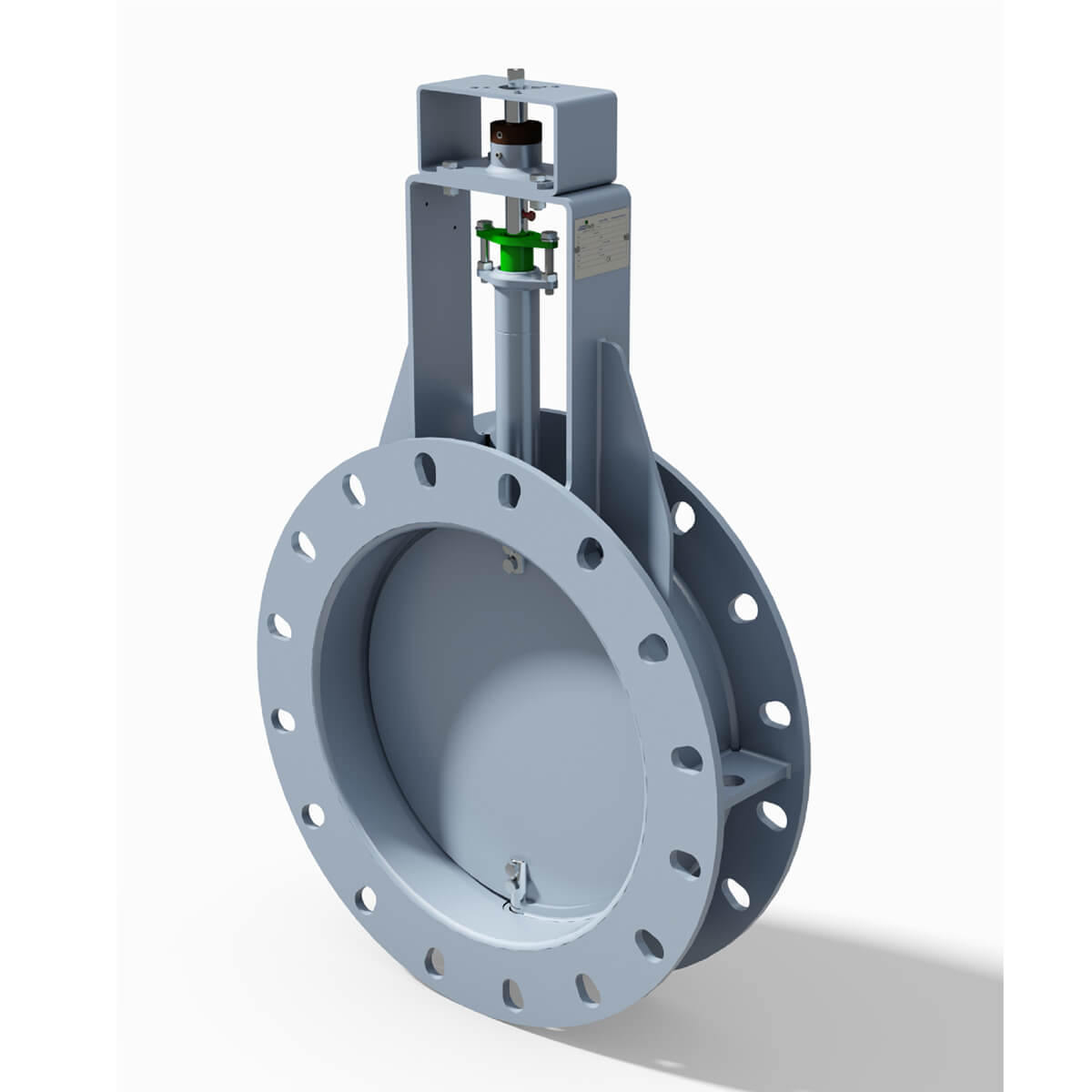

Aluminium Butterfly Valve

On-Off or modulating service

DN 100 – 400

Connections : Wafer Flanged

Material: Aluminium, 316SS – 304SS – Carbon Steel

On-Off or modulating service

DN 100 – 400

Connections : Wafer Flanged

Material: Aluminium, 316SS – 304SS – Carbon Steel

Another important step in the growth process of AMMcut, led to the birth of the new industrial painting brand: AMMcolor.

The need is to offer a service of surface treatments and industrial painting guaranteeing its customers a complete service and characterized by high quality standards.

AMMcolor specializes in industrial painting and anti-corrosive treatments, with the possibility of powder, liquid and customised RAL, galvanizing primers, peeled or shriveled coating and smooth surface effects; it also performs blasting and Shot Peening treatments.

AMMcut, despite a 2020 full of uncertainties, instead proposes itself, also through the birth of this new brand, as an active and innovative company always ready to meet the needs of the local market and its customers.

The new 4 roll plate bending machine is equipped with greater calendering power and is able to offer wider versatility and better performance in conical machining.

AMMtech also through the purchase of this machine confirms its orientation towards continuous investments in technological evolution.

The high productivity, the increase in precision in the calendering of the cones, the ease of use and the technology that characterizes this machine allows us to work first of all in maximum safety.

We guarantee maximum precision in the calendering process and a performance able to speed up the processing times.

The aim is that of significantly reducing the total time of the production cycle of our valves.

AMMtech has purchased the new 4-Roller Hydraulic Bending Machine type M2010, thanks to the operation/project co-financed by the European Regional Development Fund (POR FESR 2014-2020 action 3.1.1 SUB. A3) of the Tuscan region.

![]()

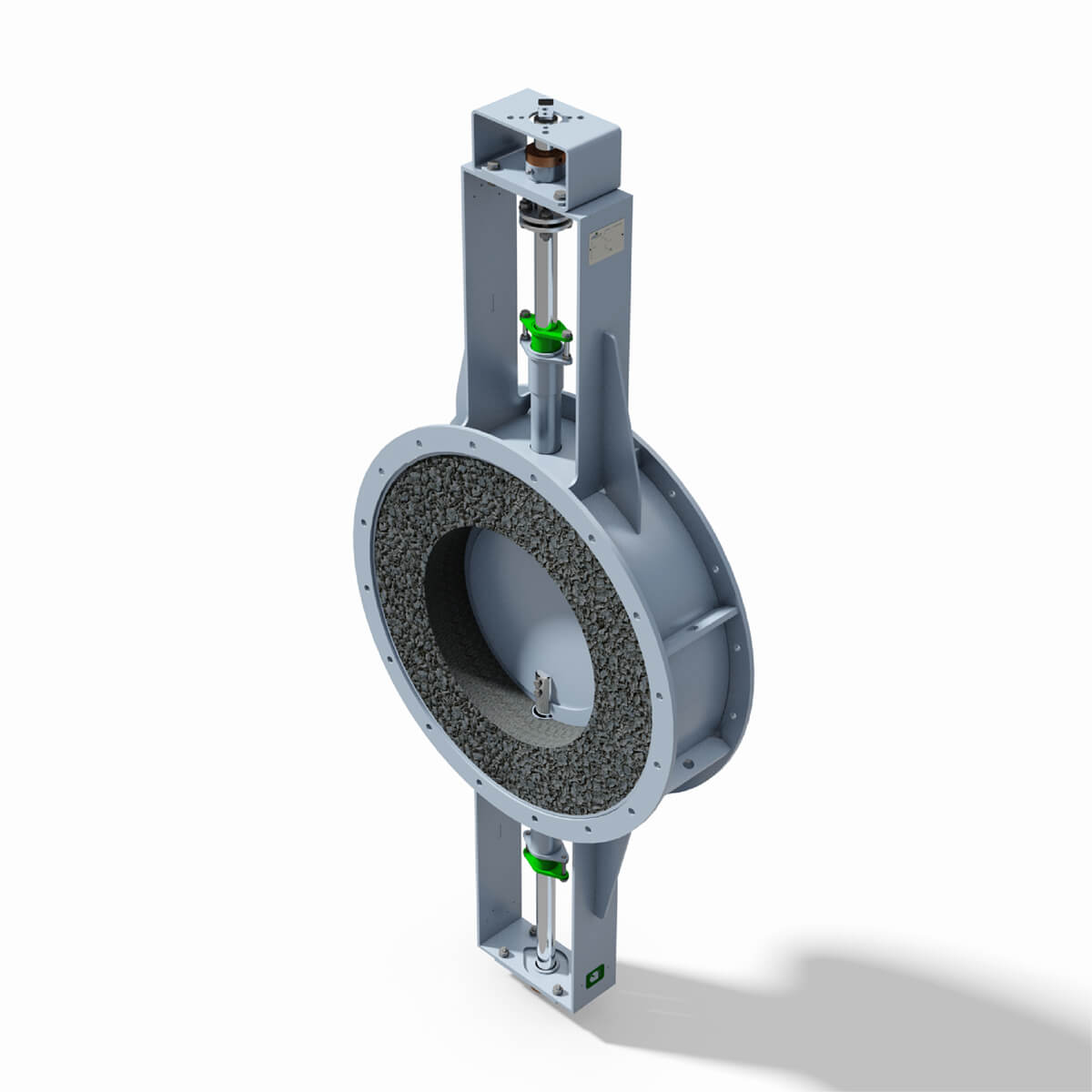

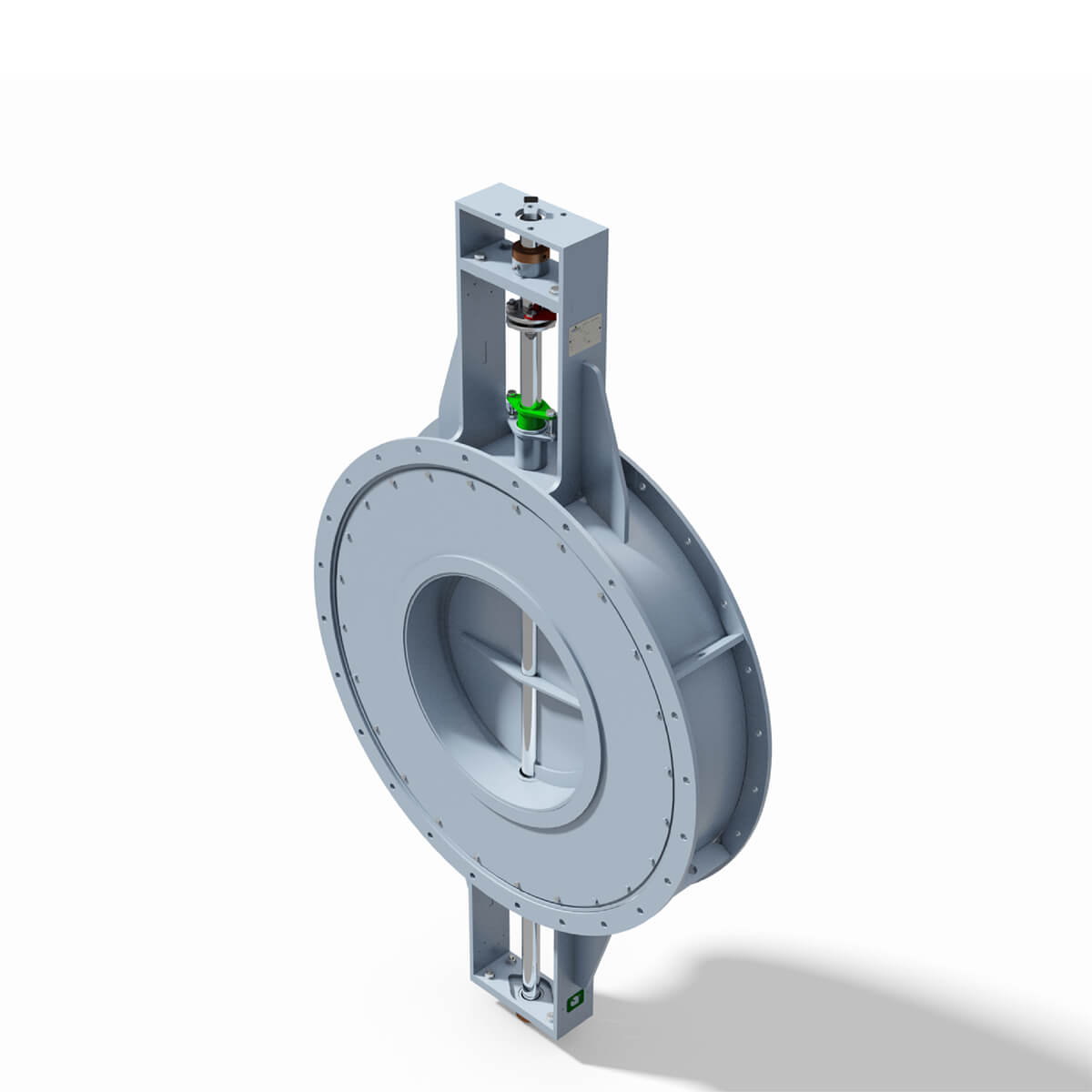

AMMtech has delivered a new project for a Spanish foundry: n. 2 Rectangular Louver Damper for fumes and High temperature up to 1100°C: dimensions 1600 × 2100 and 1600 × 2500 with Seal Air System for 100% Tightness.

AMMtech will be exhibiting at PowerGen Europe to be held in Paris from 12 to 14 November.

Come and visit us at booth H14

AMMtech has secured and delivered a new project for Sisecam Flat Glass of Manfredonia, leader in the flat glass market.

n. 1 Double Blade Damper Valve DN 2000 mod. AMM705H On-Off service

n. 1 Damper Valve DN 2000 mod. AMM708H On-Off service

n. 1 Double Blade Damper Valve DN 2000 mod. 750H Control service with Air Sealing System for perfect tightness

AMMtech presents the new website with a completely new graphics to help navigation through our website making it more pleasant and intuitive.

AMMtech will be present at Valve World America to be held in Houston – Texas from 19 to 20 June.

Come and visit us at stand 238

AMMtech thanks everyone for visiting the stand at IVS 2019 and for the interest shown towards the products.

We remind you that we are available for any request, advice or clarification regarding the application of our Damper Valves.

In April the expansion of the production site and the new offices was inaugurated.

The need arose from the urge to implement the production area to cope with continuous growth and the consequent increase in fabrication.

Even the creation of new technical and commercial offices was the result of the development of AMMtech, which led to the recruitment of new staff.

AMMtech has delivered n. 2 Damper Gas Distributor ByPass 2700 × 2700 inside DN, with seal for perfect tightness.

The valves will be installed at Gazprom’s Portovaya Liquid Natural Gas plant in Russia and used for boiler flue gas recovery.

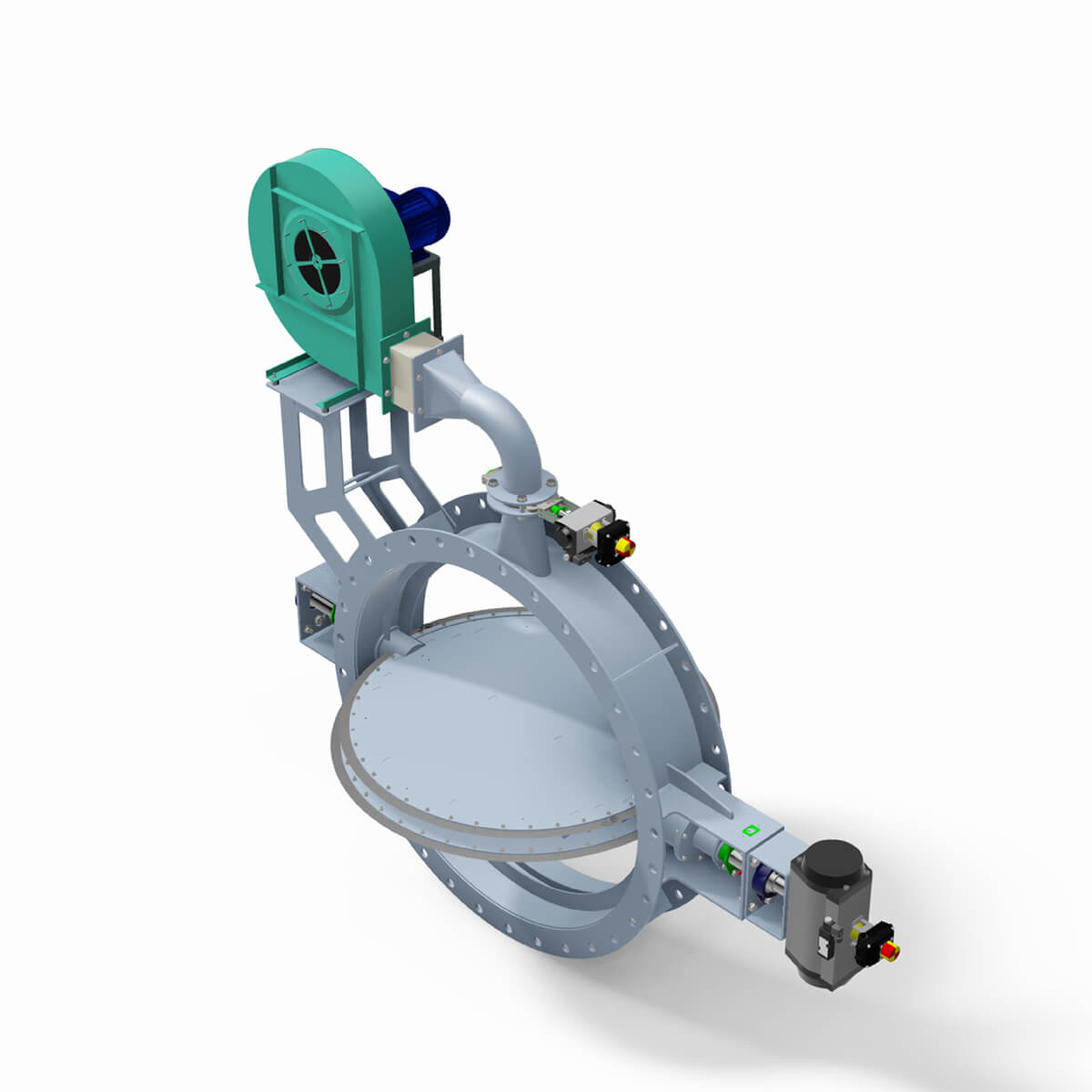

AMMtech, in order to face the huge demand of the marine sector for seal air damper has dedicated an entire technical-production area for the manufacture of type AMM750. This damper is used in exhaust gas treatment systems installed on ships.

AMMtech has secured and delivered a project for n. 1 Guillotine Damper rectangular section 2130 × 3930 and n. 1 Guillotine Damper Rectangular Section 2130 × 2780 electrically operated. These valves will be installed in flue gas recovery system for new steam production. The steam will be used to make pickling and vacuum through special injectors.

AMMtech, with the aim of enhancing and promoting young local talents, confirms the sponsor to Riccardo Pera.

The young nineteen year old from Lucca aims at winning the European Endurance title with the Porsche 911 RSR. This year he will race with the official Porsche team of the Proton Competition.

In fact, after the performances obtained in 2018 with 4 podiums at its European debut, the victory of SPA, the pole position of Monza, and the world podium in China, Porsche wanted to invest in Riccardo.

The championship will take place on 6 events:

April 14th Le Castellet (F)

May 12th Monza

July 21st Barcelona (E)

August 31st Silverstone (GB)

September 22nd SPA (B)

October 27th Portimao (P)

AMMtech has delivered n. 2 Seal Air Diverter Dampers 2600 × 2600 for Waste Heat Recovery Unit (WHRU) Siemens plant in USA Lincoln County N.C.

On-Off or modulating service

DN 100 – 400

Connections : Flangiate

Material: Carbon Steel, AISI 304, AISI316

On-Off or modulating service

DN 50 – 600

Connection: Wafer

Material: Ghisa, AISI316

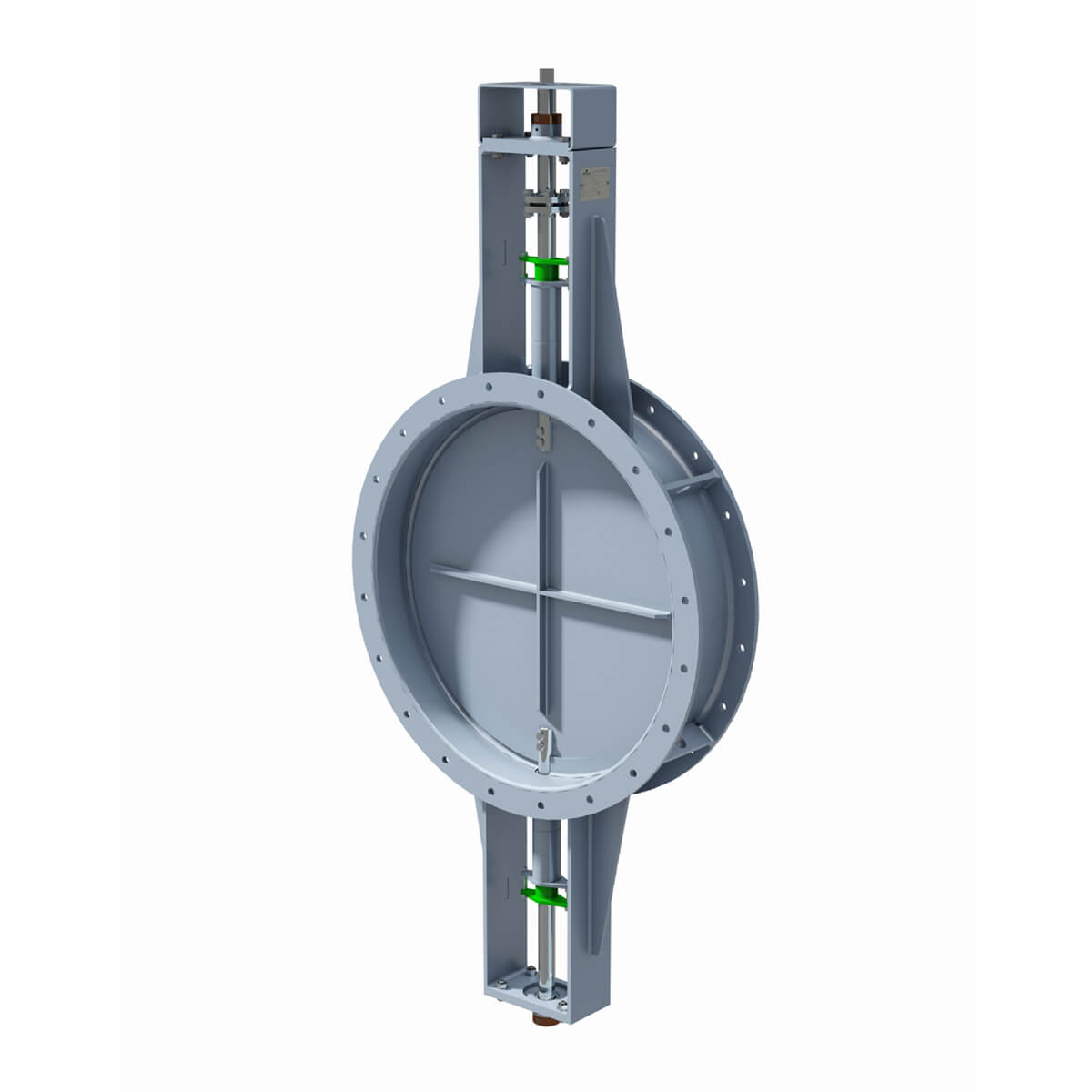

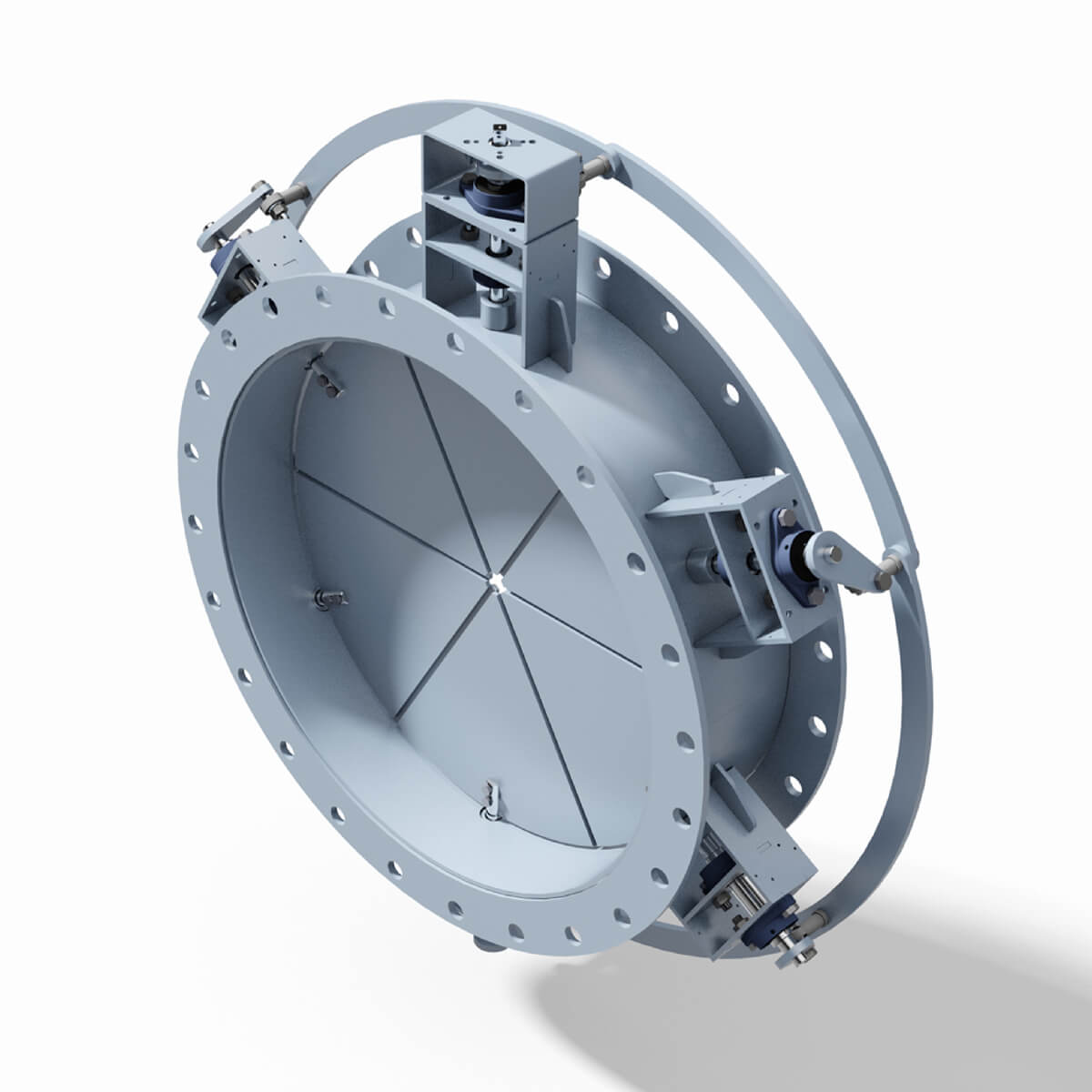

Circular, Square, Rectangular section

Servizio On-Off o Modulante

DN 150 -2500

Max Leakage Class III (FCI 70-2)

End Connections: Wafer, Flanged

Material: Carbon Steel, AISI 304, AISI 316

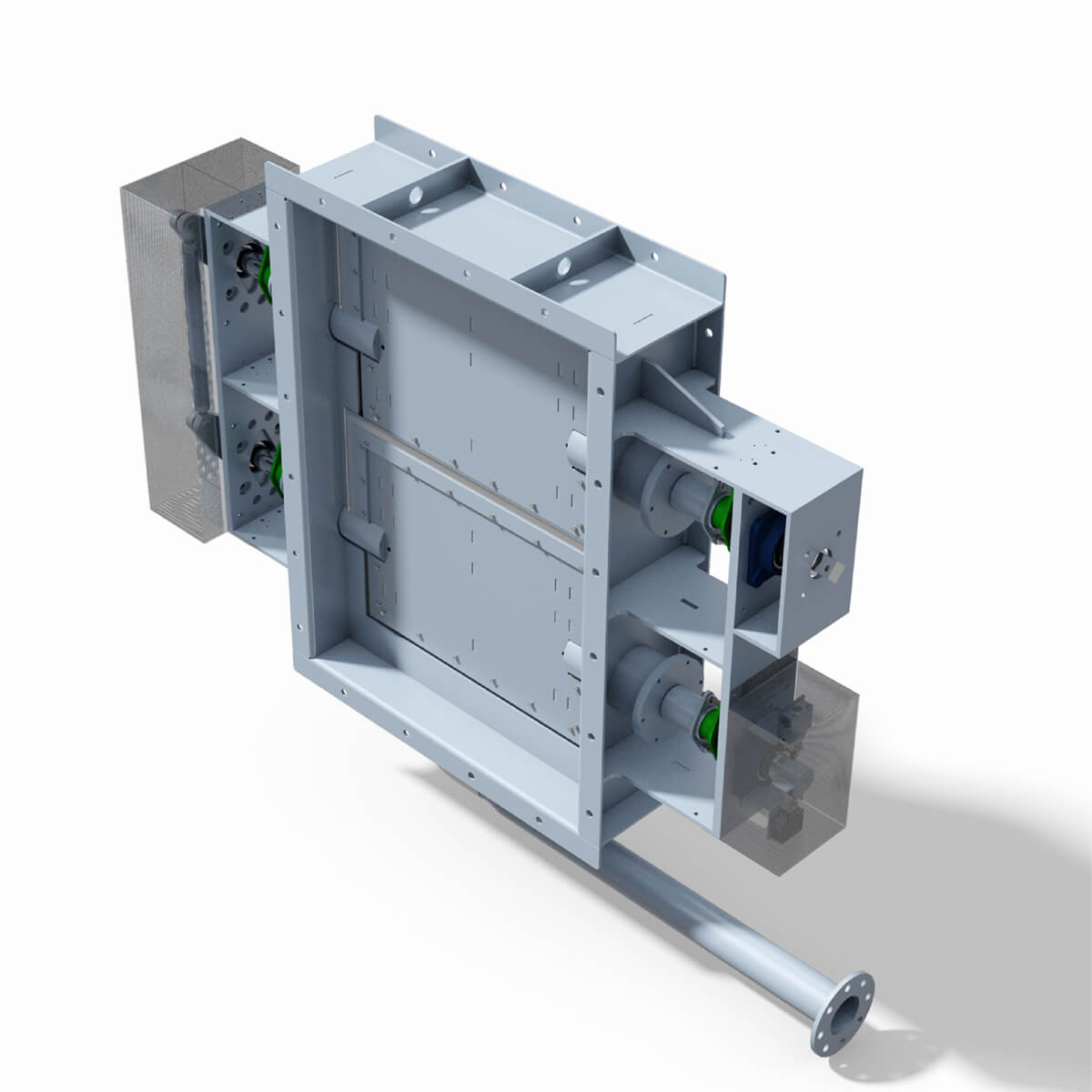

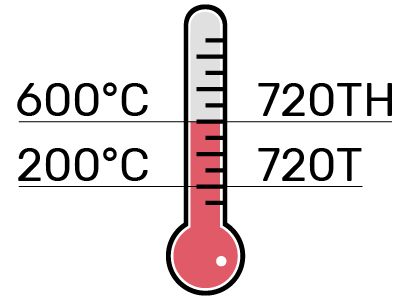

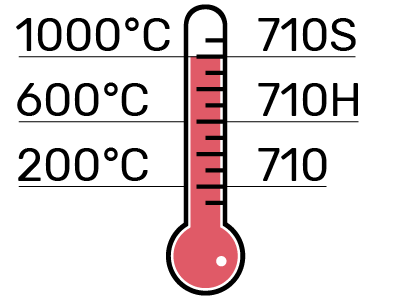

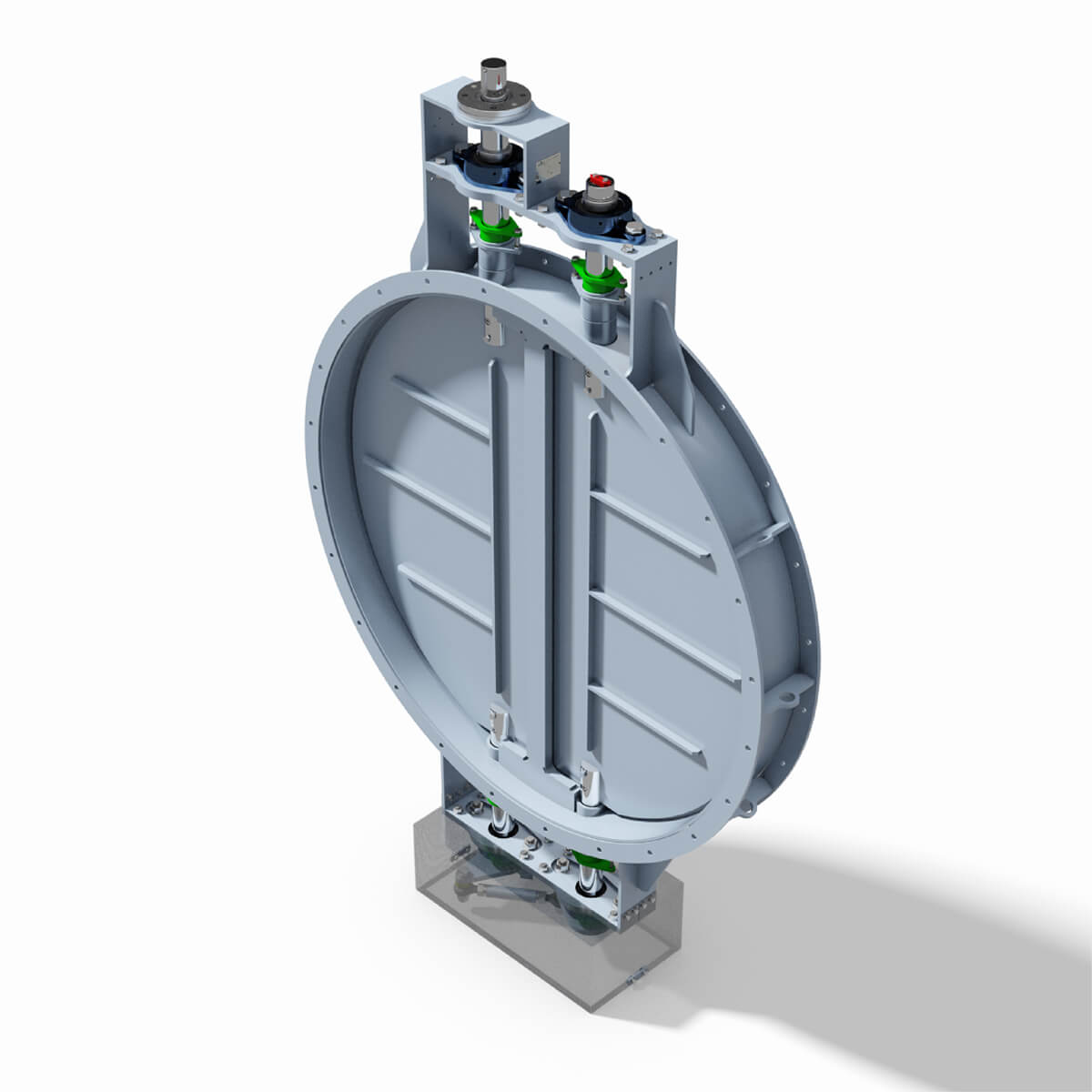

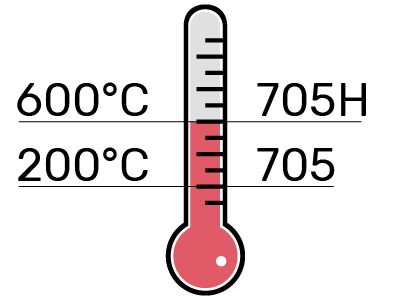

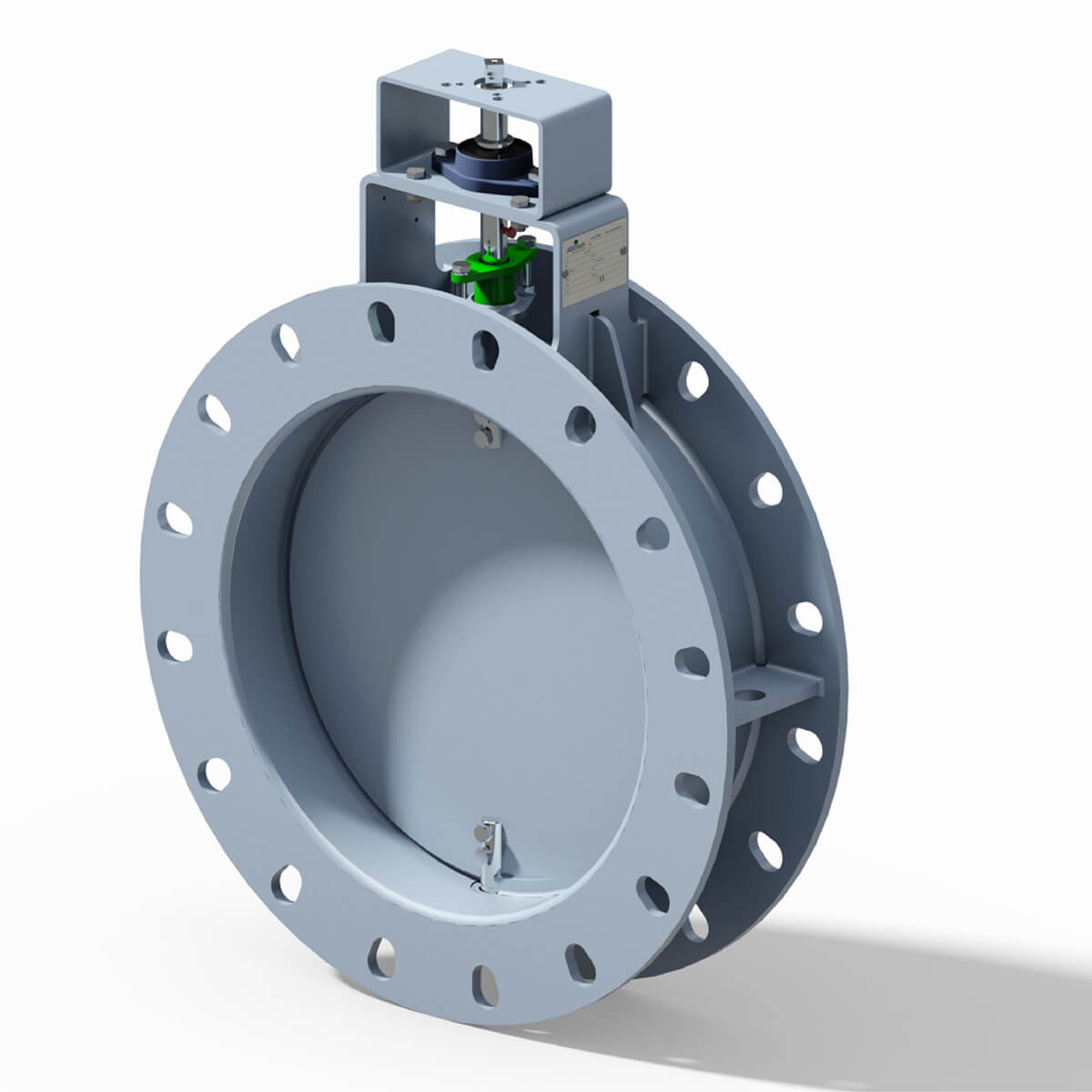

For Control or On/Off Service

DN 150 -2500

Max Leakage Class III (FCI 70-2)

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316, AISI 310, AISI 321

For Control or On/Off Service

DN 150 -2500

Max Leakage Class III (FCI 70-2)

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316, AISI 310, AISI 321

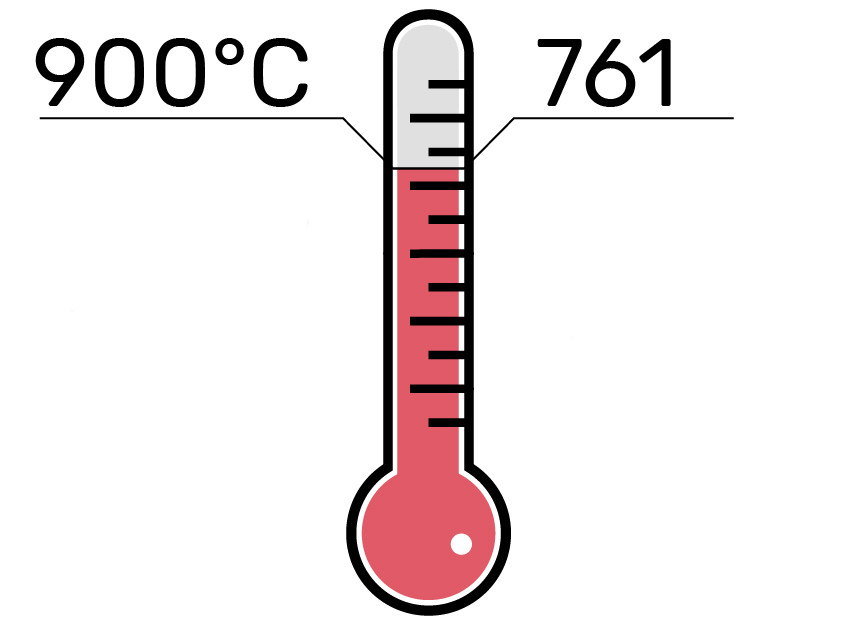

For Control or On/Off Service

DN 150 -1500

Max Leakage Class III (FCI 70-2)

End Connections: Wafer, Flanged

Material: AISI 310, AISI 321

Size Range upon request

For Control or On/Off Service

Max Leakage Class III

(FCI 70-2)

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316

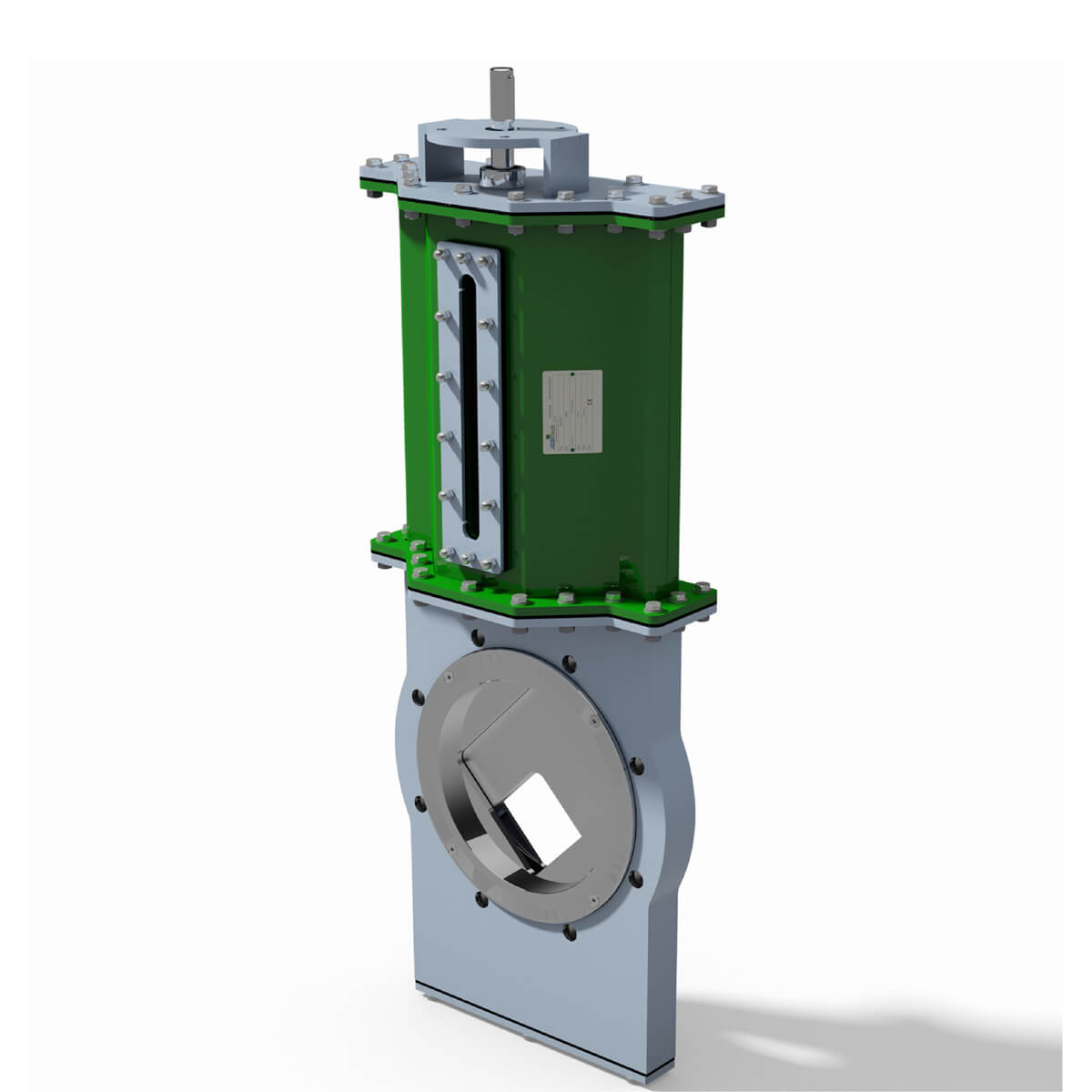

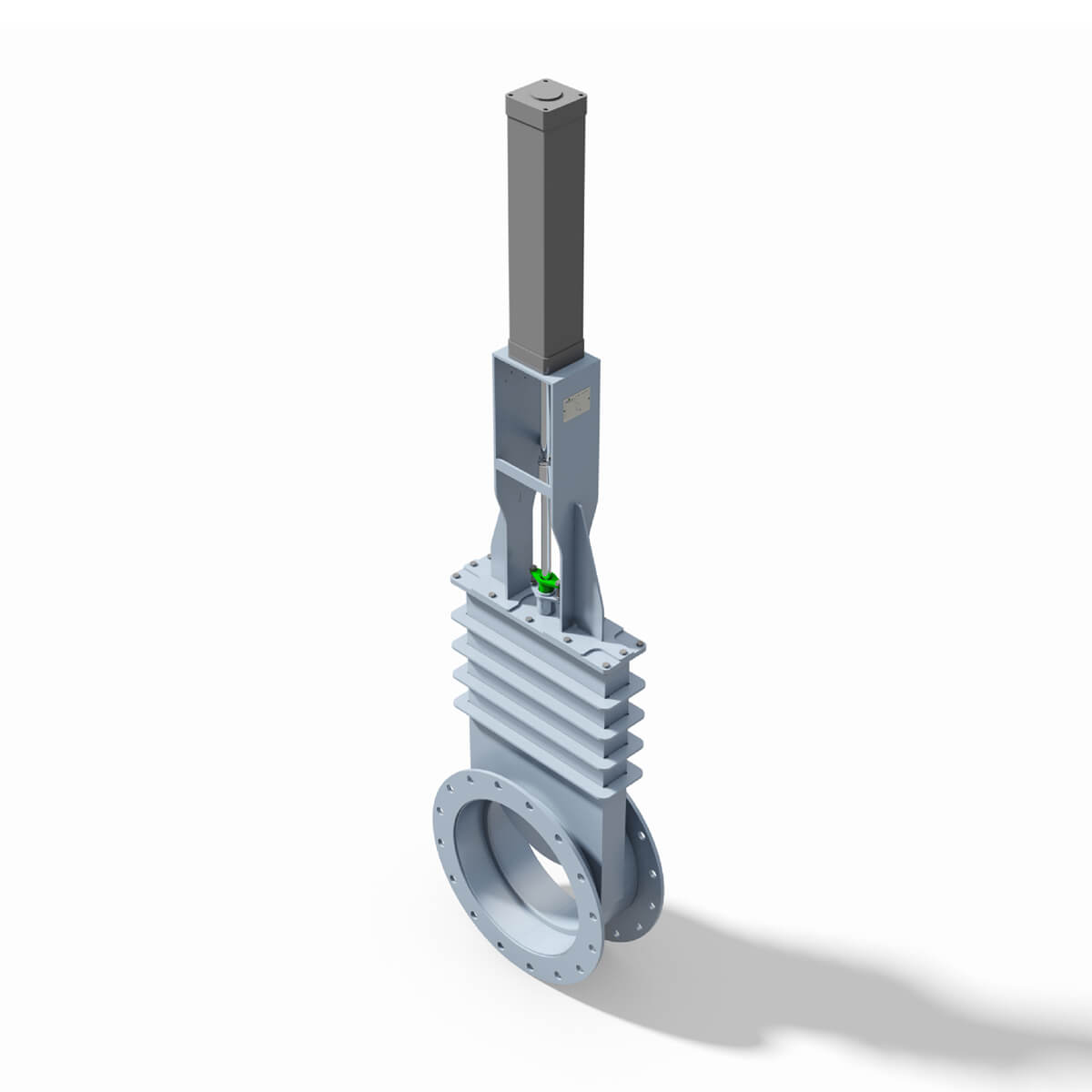

Circular, Square, Rectangular section

For Control or On/Off Service

DN 100 – 3000

Max Leakage Class ØLeakage Tenuta Perfetta

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316, AISI 310, AISI 321

For Control or On/Off Service

DN 100 – 2500

Max Leakage Class III (FCI 70-2)

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316

For Control or On/Off Service

DN 150 – 3000

Max Leakage Class VI (FCI 70-2) Ø- Tenuta perfetta con aria di sbarramento

End Connections: Wafer, Flanged

Material: Carbon Steel, Corten, AISI 304, AISI 316

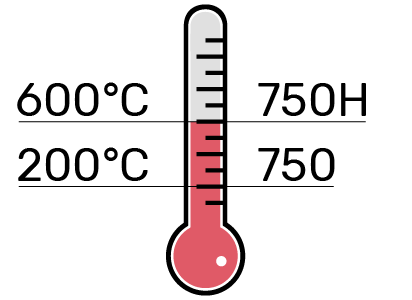

For Control or On/Off Service

DN 150 – 2000

Max Leakage Class VI Ø Leakage – Total Tightness (FCI 70-2)

End Connections: Wafer, Flanged

Material: Carbon Steel, AISI 304, AISI316

Seat: FEP, PFA

For Control or On/Off Service

DN 150 – 2000

Max Leakage Class VI (FCI 70-2) – Tenuta Perfetta

End Connections: Wafer, Flanged

Material: Carbon Steel, AISI 304, AISI316

Seat: Silicon, NBR, Viton, EPDM

For Control or On/Off

Service DN 150 -1500

Max Leakage Class III (FCI 70-2)

End Connections: Wafer, Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316

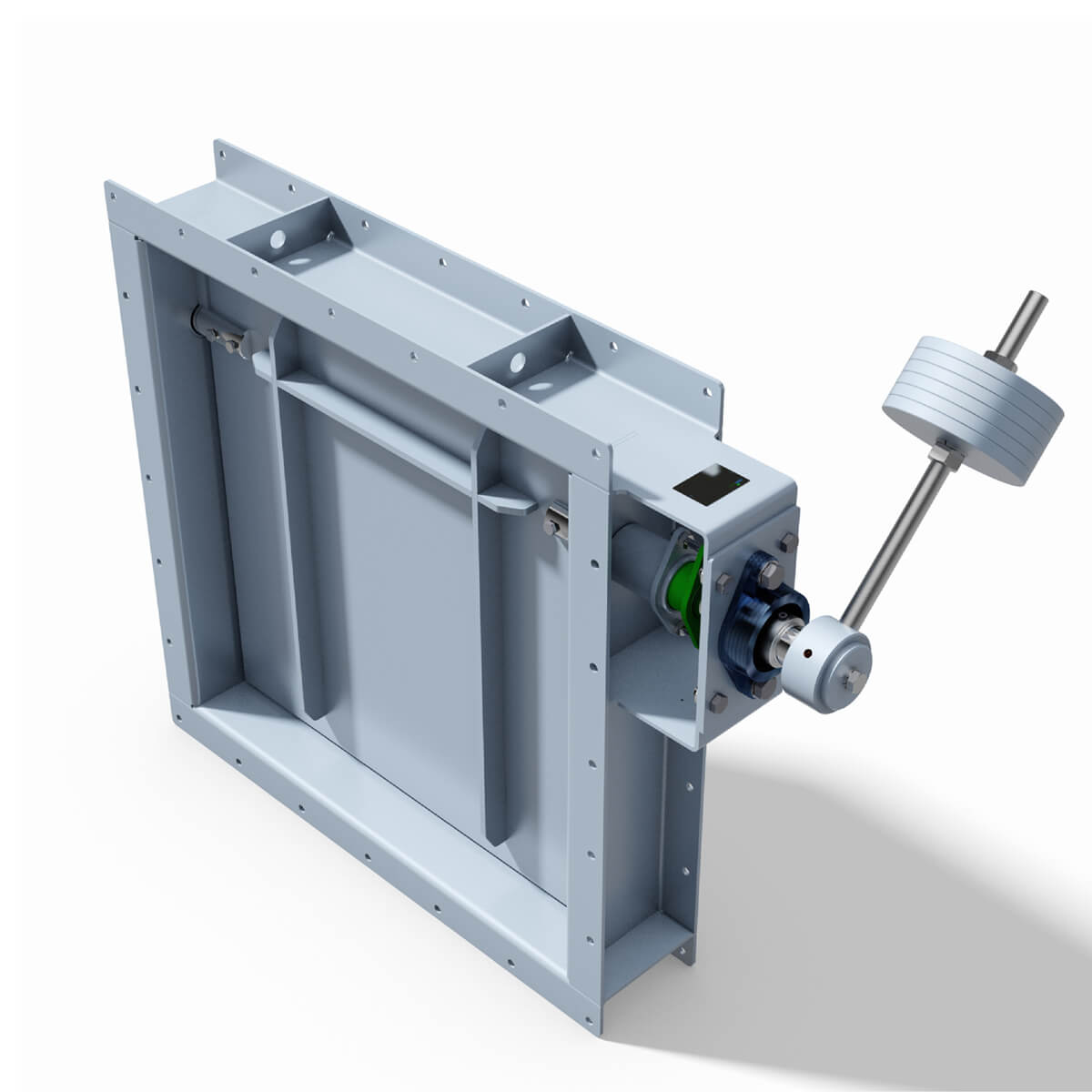

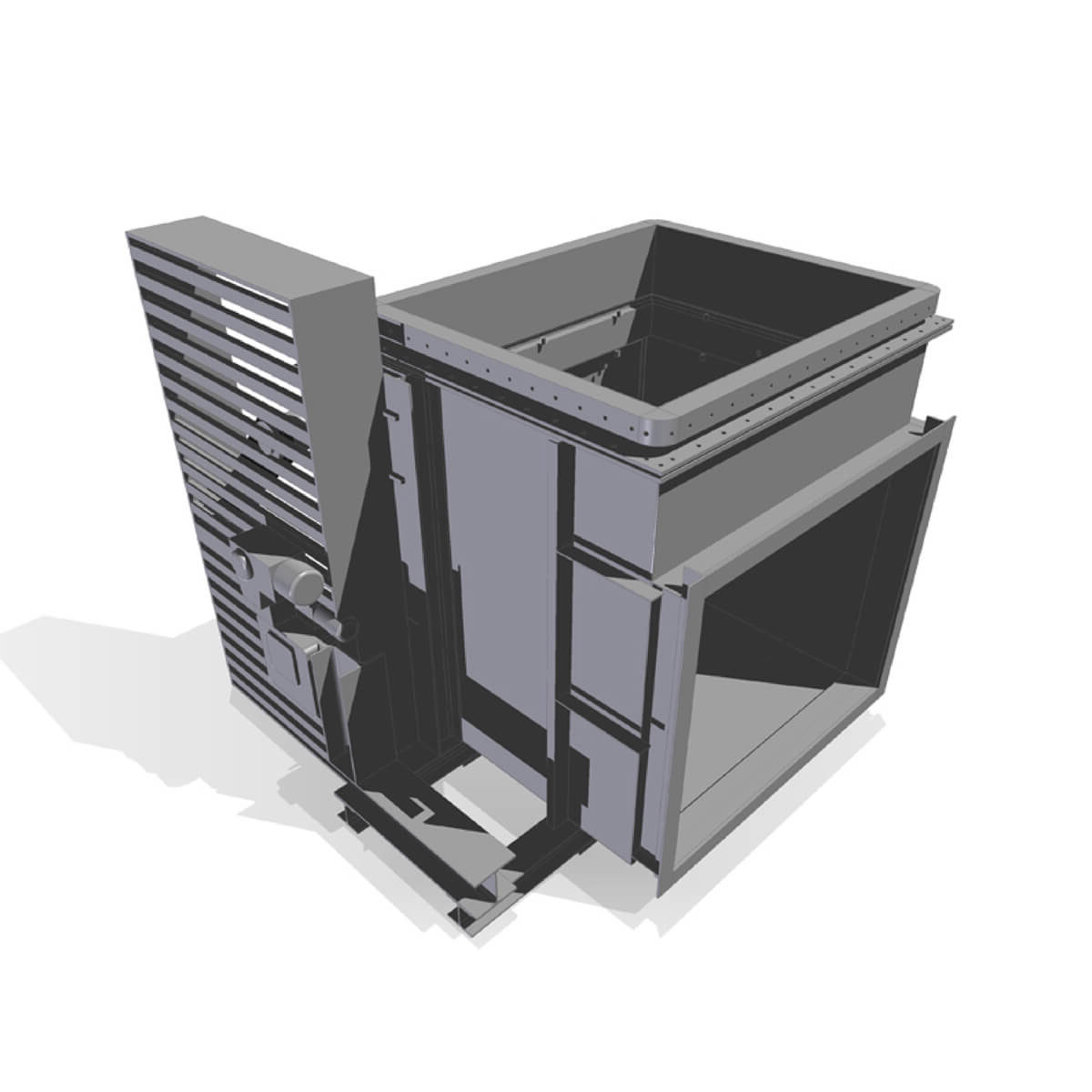

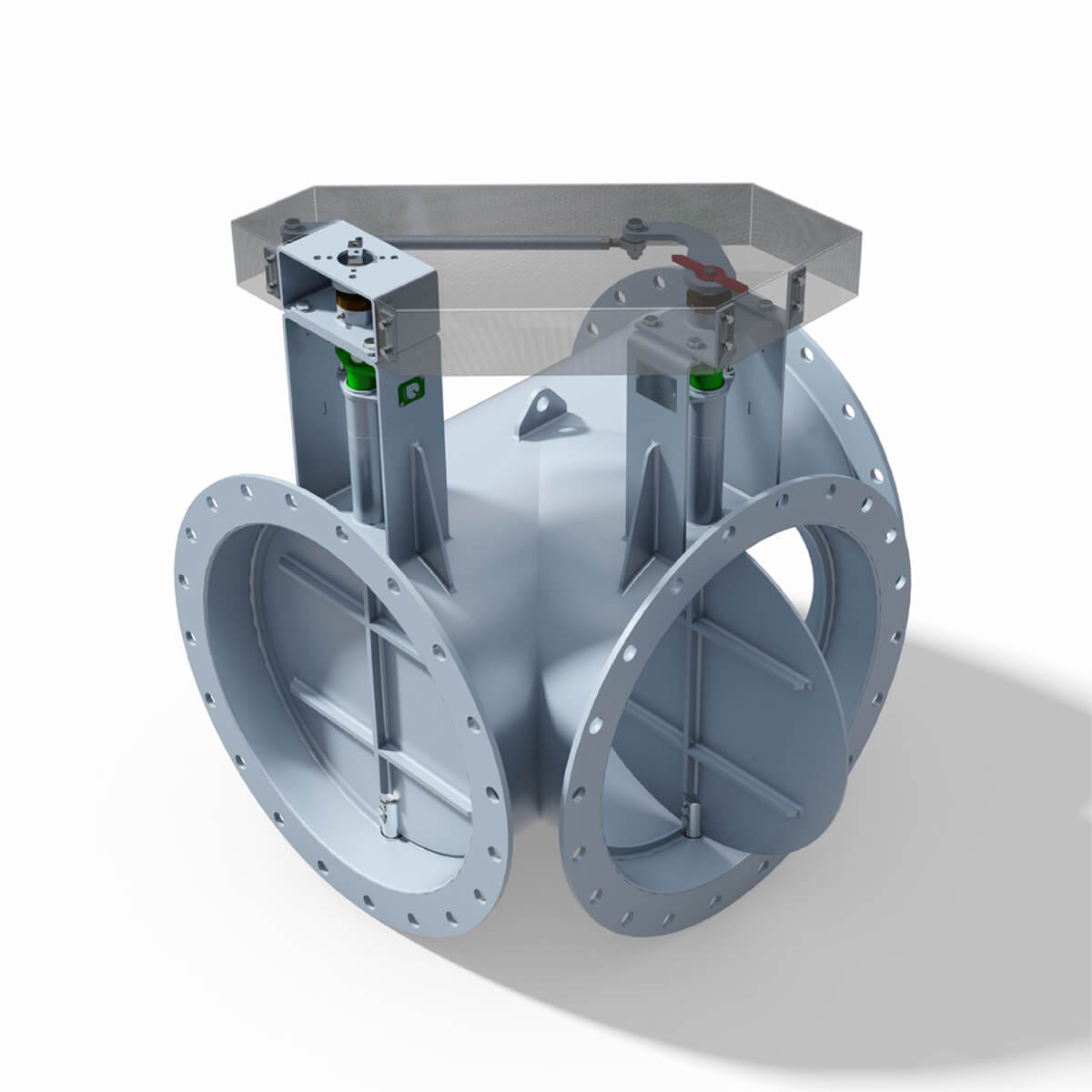

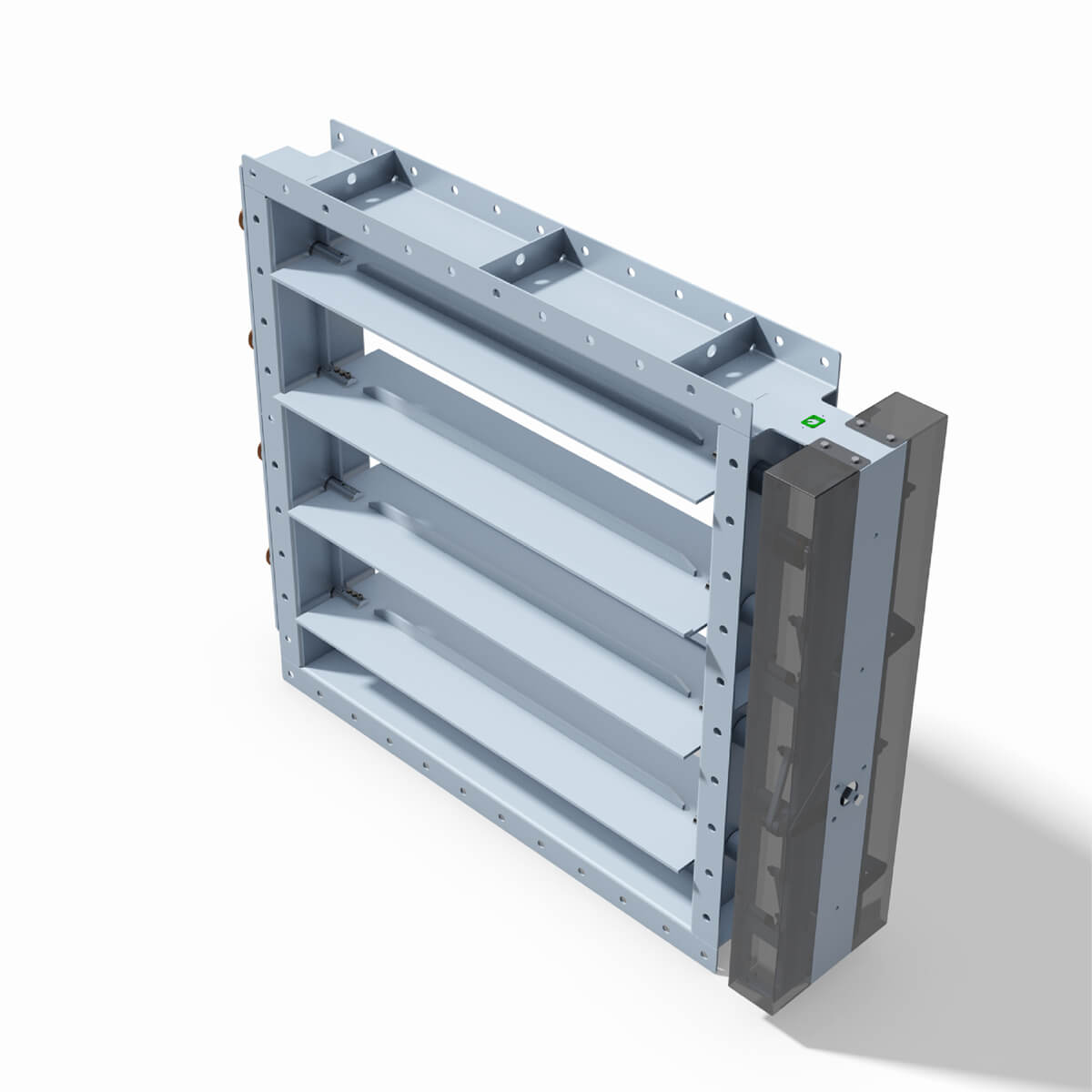

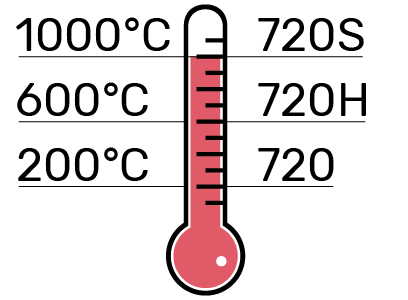

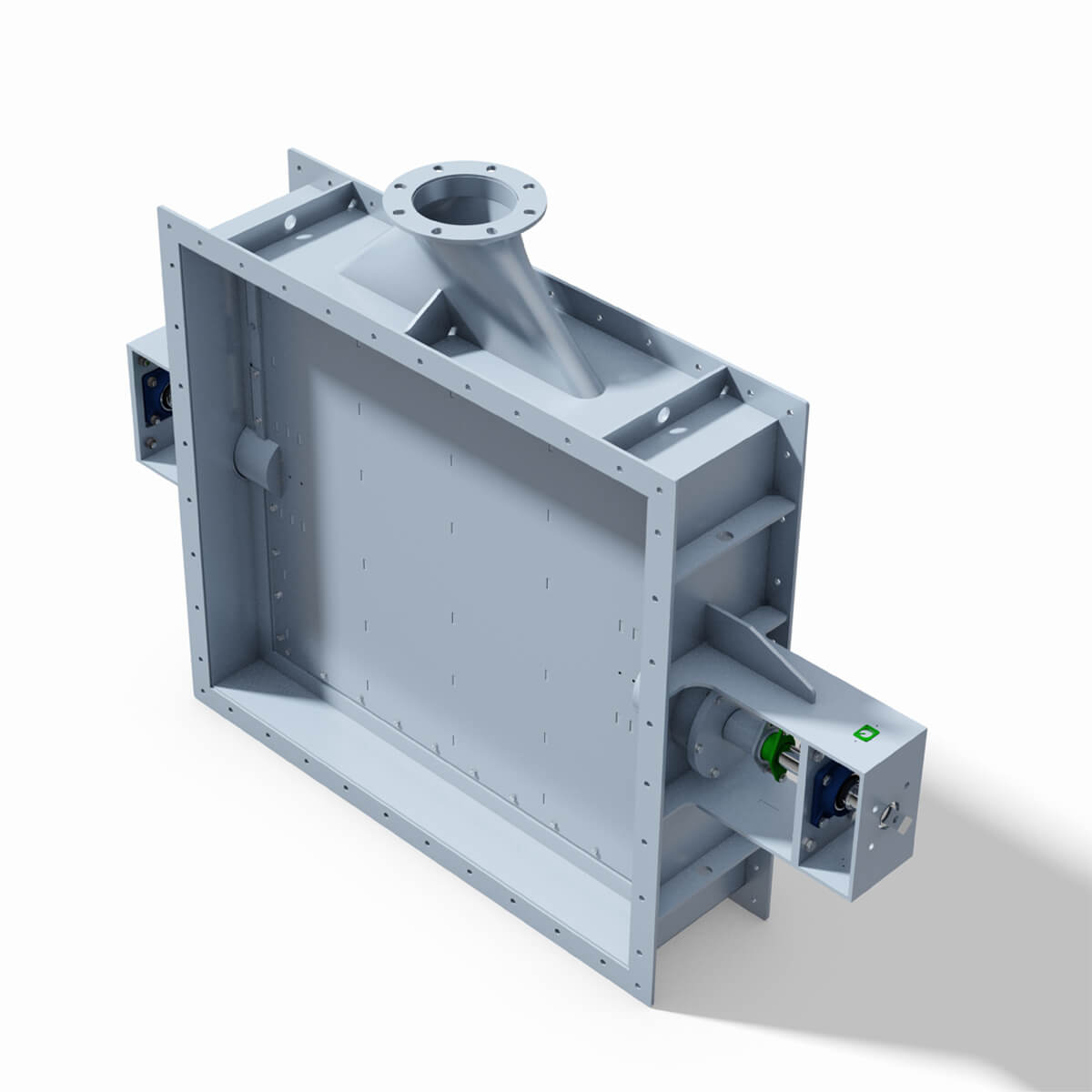

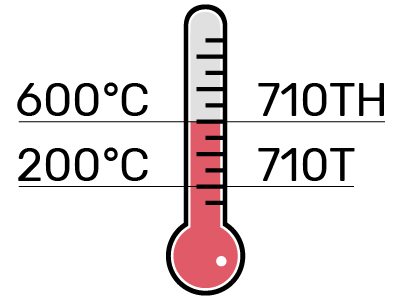

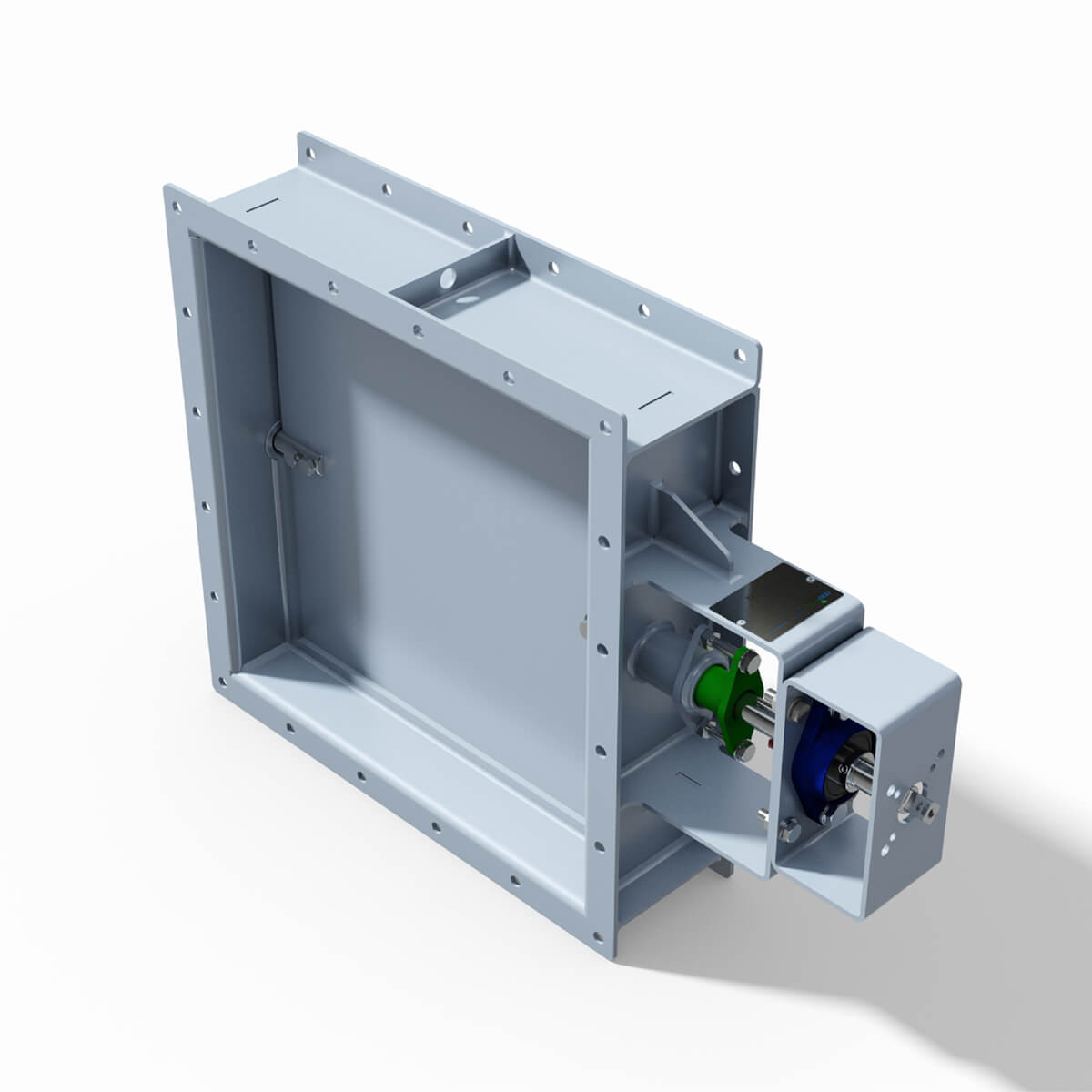

Rectangular or Square section

Modulating Service

Size Range upon request

Total Tightness 100%

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316

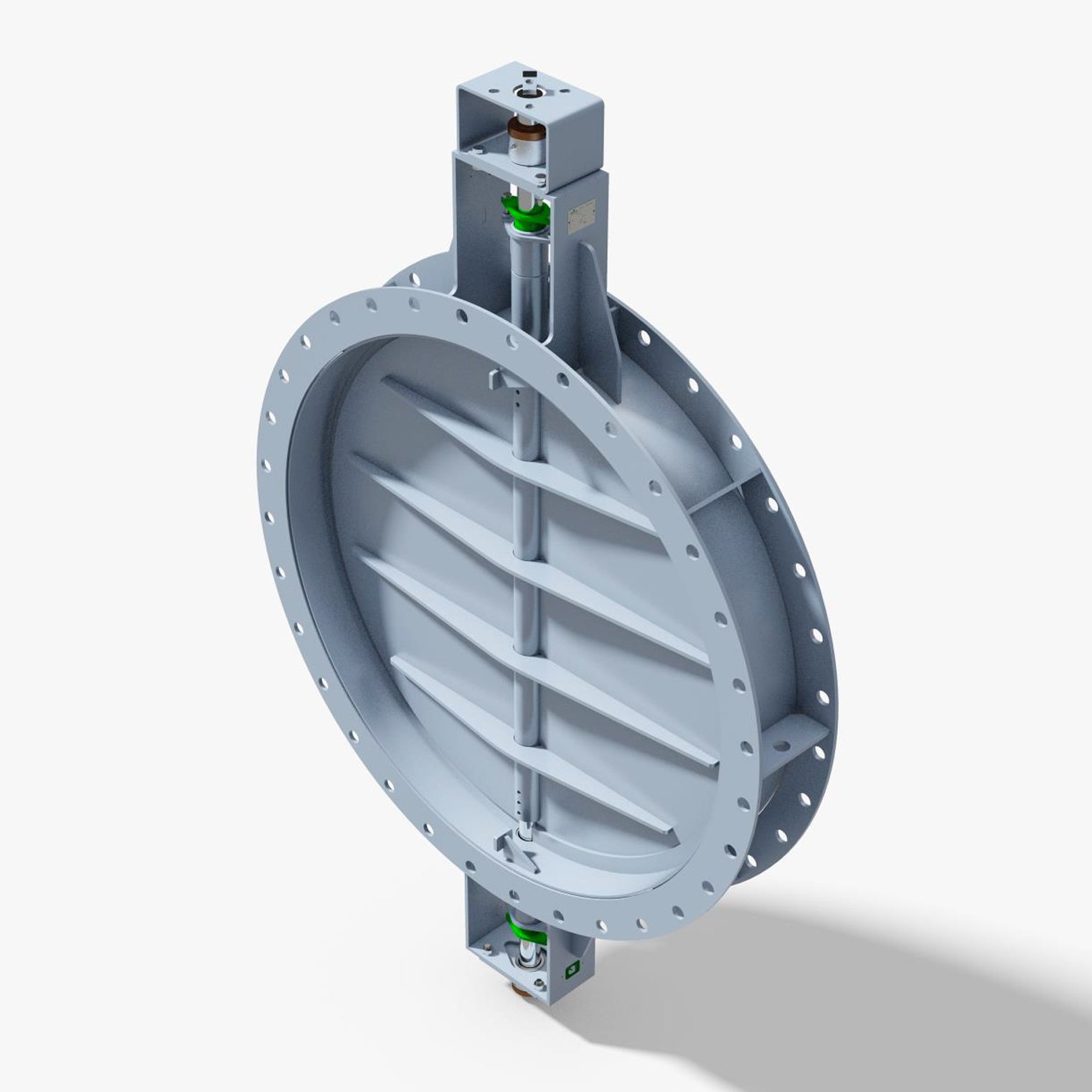

Rectangular or Square section

Modulating Service

Size Range upon request

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316, AISI 310, AISI 321

Modulating Service

DN 300 -2000

End Connections: Flanged

Material: Carbon Steel, AISI 304, AISI316

Rectangular or Square section

For Control or On/Off Service

Size Range upon request

Total Tightness 100%

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316

Rectangular or Square section

For Control or On/Off Service

Size Range upon request

End Connections: Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316, AISI 310, AISI 321

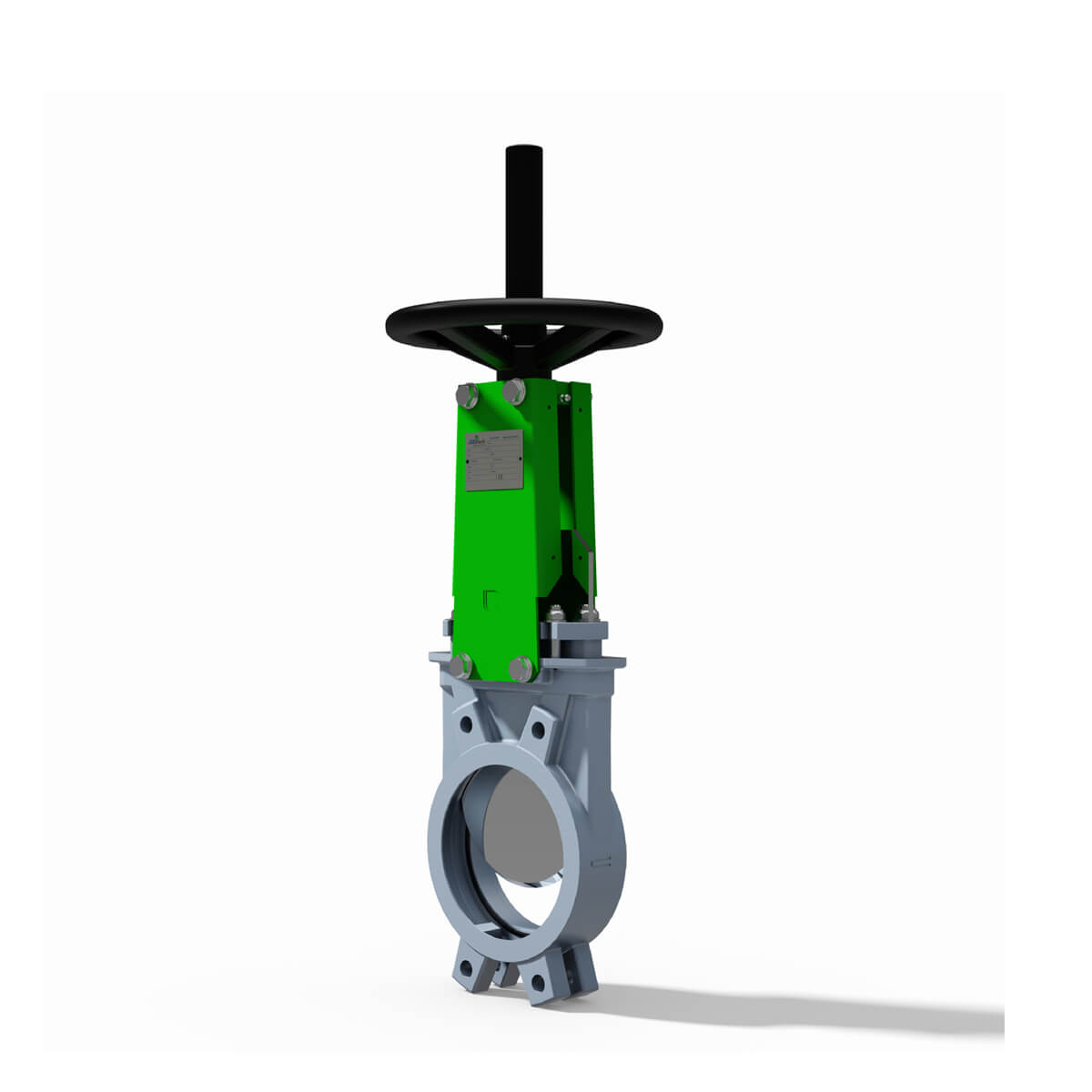

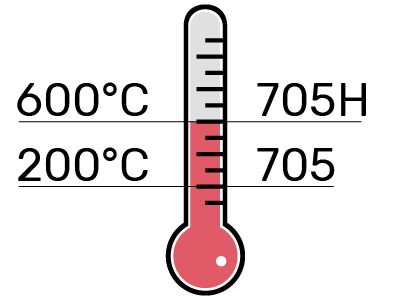

For Control or On/Off Service

DN 200 -3000

Max Leakage Class III (FCI 70-2)

End Connections: Wafer, Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316

Modulating Service

DN 300 – 3000

End Connections: Wafer, Flanged

Material: Carbon Steel, Corten, AISI 304, AISI316

For Control or On/Off Service

DN 50 – 300

Max Leakage Class II (FCI 70-2)

End Connections: Wafer

Material: AISI316

Servizio On-Off o Modulante

DN 150 -1500

Max Leakage Class III (FCI 70-2)

End Connections: Wafer, Flanged

Material: Carbon Steel, AISI 304, AISI316